Cast Aluminum Overview

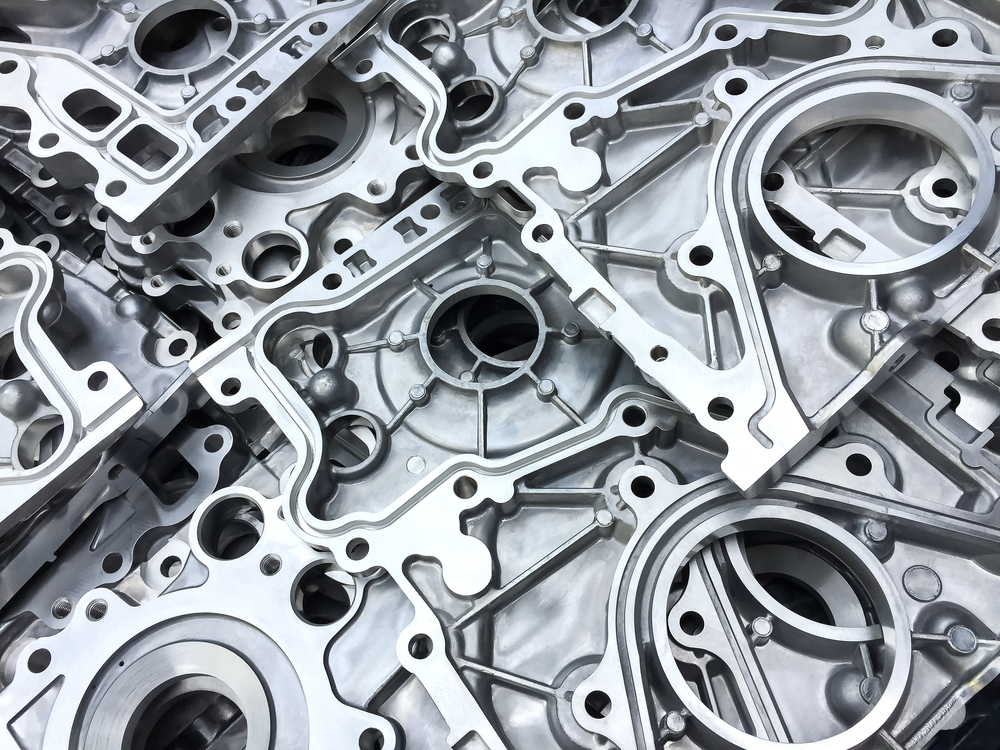

Cast aluminum refers to aluminum (Al) that has undergone a casting process, where the metal is melted and poured into a mold to solidify into various shapes. This method enables the production of parts with complex geometries that might be challenging to achieve through other manufacturing processes.

Key Characteristics

Key characteristics of cast aluminum include its lightweight nature, which is particularly beneficial in industries where reducing weight is crucial, such as automotive and aerospace. Despite its low density, cast Al maintains excellent strength and durability, making it resistant to corrosion and wear. Its superior thermal conductivity also makes it ideal for applications requiring efficient heat distribution, such as cookware and automotive components.

Manufacturing Methods

There are several casting methods used for aluminum, including die casting, sand casting, and permanent mold casting. Die casting is favored for high-volume production due to its ability to produce parts with tight tolerances and smooth finishes. Sand casting is suitable for larger, more complex shapes but results in a rougher surface finish. Permanent mold casting offers a balance between the two, providing good surface finish and dimensional accuracy for medium to high volume production.

Applications Across Industries

Cast Al is utilized across various sectors. In the automotive industry, it is used for parts like engine blocks and wheels to reduce vehicle weight and improve fuel efficiency. The aerospace sector values it for its strength-to-weight ratio. In household applications, its non-toxicity and excellent heat distribution properties make it popular for cookware and appliances. Additionally, its resistance to corrosion and lightweight nature make it a preferred choice for outdoor furniture.

Recycling and Environmental Impact

Recycling plays a significant role in the lifecycle of cast aluminum. Recycling aluminum requires approximately 95% less energy than producing new aluminum from raw materials, emphasizing its environmental benefits. Cast aluminum products can be recycled and recast, contributing to a circular economy.

Challenges and Innovations

However, challenges exist in working with cast aluminum, including issues with porosity in cast parts and some limitations in mechanical properties compared to wrought aluminum. Despite these challenges, continuous innovations in casting technologies and alloy development are expanding the applications and improving the qualities of cast aluminum.