The Mastery of Dry Granulation in Metal Recycling

Dry granulation stands as a pillar in the realm of metal recycling, breathing new life into waste materials, turning slags and dross into valuable, reusable commodities. The method, rooted deeply in innovation and refined techniques, is the architect behind converting metal-containing waste streams into pillars of economic value and environmental sustainability. Franklin Metals, a vanguard in metal recycling, leverages this technology to usher in a new era of efficient and sustainable metal recovery.

Understanding Dry Granulation

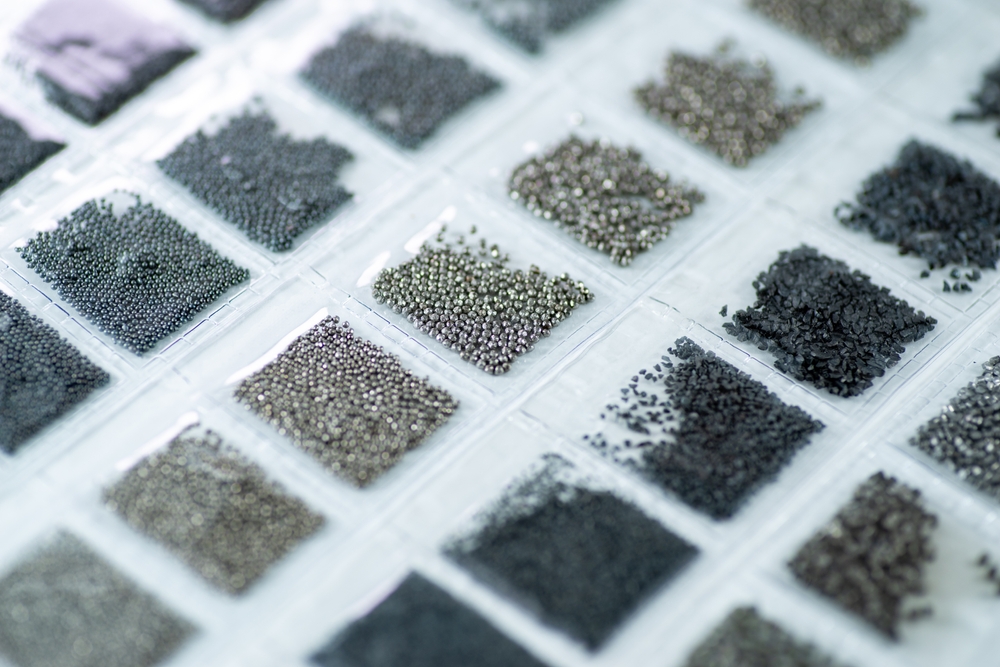

Dry granulation is a symphony of processes intricately woven together to metamorphose metal-containing residues into granulated forms, setting the stage for the enhanced recovery of precious metals. Unlike other methods, it omits the usage of heat or extreme pressures, relying instead on simpler, efficient techniques that reduce costs and minimize environmental impact.

The Steps of Dry Granulation in Metal Recycling

Material Preparation

- Receiving and Inspection: The act begins with the collection of raw materials, where each actor, from slags to industrial residues, is meticulously inspected and prepared for the grand performance.

The Granulation Process

- Atomization: In this act, materials dance in a choreography of atomization, turning into fine droplets that enhance surface areas, preparing them for the grand drying performance.

Drying: The Transformation Act

- Hot Air Symphony: A ballet of hot air swoops in, caressing each particle, relieving them of moisture and gracefully guiding them towards granulation.

Product Collection and Curtain Call

- Separation: The granules, now transformed, are ushered into the wings, separated from the drying medium and prepared for their final act.

- Collection: Each granule, a star, is collected, awaiting the encore – the metal recovery process.

Metal Recovery: The Encore

- Pyrometallurgical Ballet: Granules may enter the fiery realms of smelting, where metals are recovered in a blaze of glory.

- Hydrometallurgical Waltz: Alternatively, a gentle waltz of leaching may unveil the hidden metals, completing the performance.

Environmental Stewardship: The Guiding Director

- Emission Control: Each performance is conducted with a vigilant eye on emissions, ensuring that the stage, our Earth, is preserved.

- Sustainable Symphony: Energy and resources are the orchestra, and the process is composed to make a symphony of sustainability.

Why Choose Dry Granulation?

The choice of dry granulation orchestrates a performance where efficiency, sustainability, and innovation are the lead actors. It directs a masterpiece that reveals the hidden potentials of waste, unlocking economic values while composing a symphony of environmental stewardship.

Franklin Metals: Your Conductor in Metal Recycling

Guided by the baton of experience and expertise, Franklin Metals conducts this symphony of dry granulation with mastery and precision. With us, you are invited to a performance where innovation orchestrates success, sustainability directs actions, and where each granule plays a part in composing a future of endless possibilities.

Conclusion

Dry granulation, a masterpiece of metal recycling, is a performance of brilliance conducted on the stage of innovation. Franklin Metals invites you to be part of this transformative symphony, where each note resonates with possibilities, sustainability, and unparalleled expertise. In the concert hall of metal recycling, our dry granulation performance ensures your recycling efforts are met with standing ovations in efficiency, value recovery, and environmental responsibility.